The Birth of a Sanhai Bubble Bag

A modern marvel of packaging technology, the Sanhai bubble bag begins its journey with meticulous raw material selection. High-quality polyethylene serves as the backbone of this durable product. Environmental considerations are at the forefront of our sourcing strategy, ensuring that each piece aligns with our robust sustainability efforts.

Raw Material Selection

Sourcing high-quality polyethylene is pivotal for creating resilient and efficient bubble bags. We assess suppliers meticulously to ensure materials meet strict quality standards while prioritizing eco-friendly practices in mining and processing.

Environmental considerations extend beyond mere compliance; they are integral to our ethos. Our commitment includes partnerships with green-certified vendors and investment in sustainable technologies to minimize carbon footprints.

Initial Processing

The transformation of polyethylene into bubble wrap film commences with melting and extrusion—a process where raw materials are liquefied and forced through a die to form a continuous sheet. This foundational layer sets the stage for subsequent crafting steps.

Crafting the Bubble Wrap

Bubble formation ensues through precise vacuum creation and molding techniques. Uniformity in bubble size and strength is paramount for functionality and durability. As bubbles emerge evenly spaced and identical, the essential cushioning property takes shape.

Layering and bonding come next—lamination fortifies the structure by integrating additional layers to bolster resilience. Rigorous quality tests validate these enhancements, confirming each roll meets stringent durability benchmarks.

Customization and Design

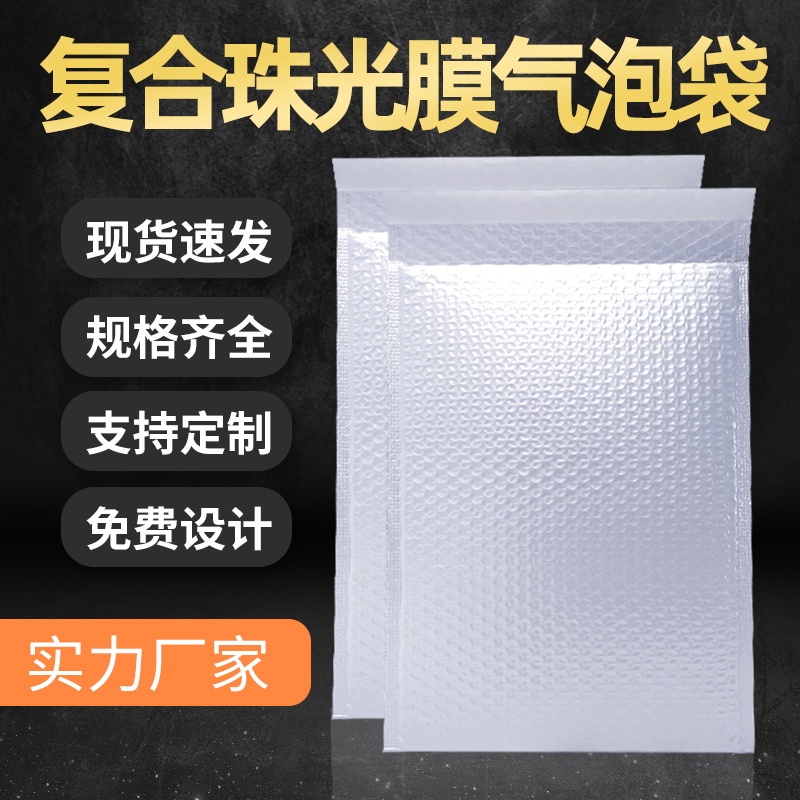

No two packaging needs are alike, which is why customization forms an intrinsic part of our manufacturing philosophy. Whether standard or bespoke sizes, every cut conforms to the unique specifications of diverse clientele.

Size and Shape Customization

We cater to varied demands by cutting bubble wrap to myriad dimensions, including custom orders tailored for specific applications. This versatility ensures Sanhai bubble bags fit seamlessly within different operational frameworks.

Innovative printing and branding options enable clients to personalize their bubble wrap. Logos, texts, and designs can be imprinted using non-toxic inks, ensuring aesthetic appeal without compromising safety or environmental standards.

Packaging and Quality Assurance

Before any Sanhai bubble bag reaches customers, it undergoes extensive inspection procedures. Visual and physical checks capture potential defects, with weight and thickness measurements ensuring each batch adheres to set criteria.

Packaging for Shipment

Post-inspection, products are methodically wrapped and boxed. Our packing protocols prioritize minimizing the ecological impact—eco-friendly packaging solutions underscore our pledge to sustainability throughout the supply chain.

Logistics and Distribution

Efficient logistics hinge on robust storage and inventory management systems. Climate-controlled warehouses preserve material integrity, while sophisticated tracking oversees stock quantities and movement.

Transportation Planning

Reliable shipping partners are crucial for timely deliveries. We engage trusted carriers and meticulously coordinate schedules to ensure seamless logistics from factory floor to end-user doorstep.

Final Delivery to Customer

Sanhai's commitment extends beyond mere delivery—exemplary customer service fortifies our brand reputation. Addressing inquiries and resolving issues promptly fosters trust and satisfaction among our clientele.

End-User Applications

Sanhai bubble bags find versatile use across industries—from safeguarding fragile items in transit to acting as insulative barriers in sensitive electronics packaging. We advocate for recycling and reusing bubble wrap through educational initiatives promoting environmental responsibility.

Innovations and Future Trends

Continual innovation propels us toward future-ready solutions. Cutting-edge materials and advanced manufacturing technologies promise enhancements in performance and efficiency. Smart packaging innovations also loom on the horizon, combining intelligence with practicality.

Sustainability Initiatives

Sustainability remains a cornerstone of our evolution. We tirelessly explore eco-friendly alternatives and commit to reducing the carbon footprint associated with bubble bag production. Future endeavors will drive further alignment with global green goals, shaping a cleaner, greener industry landscape.

Welcome to Jinhua Sanhai Packing Products Co., LTD! Should you wish to delve deeper into our offerings, including co-extruded film bubble envelope bags and black thickened bubble bags, our team stands ready to assist. For bulk orders or enquiries, contact us today!